MG SERIES CAM CLUTCHES

MG SERIES CAM CLUTCHES

Other introductions:

Size and performance

| Model | Max.Torpue (N.m) | Max.Overunning | Stock Bore Size | A | B(h7) | C | ||

| lnner Race | Outer Race | Dia (H7) | Keyway | |||||

| MG300 | 314 | 2800 | 900 | 19 | 5x2 | 63 | 77 | 60 |

| MG400 | 539 | 2600 | 800 | 22 | 5x2 | 70 | 88 | 67 |

| MG500 | 1620 | 2400 | 800 | 31.5 | 7x3 | 89 | 108 | 86 |

| MG600 | 3140 | 2100 | 700 | 50 | 12x3.5 | 95 | 136 | 92 |

| MG700 | 5880 | 1500 | 500 | 70 | 18x6 | 127 | 180 | 124 |

| MG750 | 9510 | 1800 | 600 | 85 | 24x6 | 153 | 200 | 150 |

| MG800 | 17600 | 1300 | 475 | 110 | 28x7 | 158 | 250 | 155 |

| MG900 | 24500 | 1200 | 400 | 135 | 35x9 | 165 | 300 | 160 |

| MG1000 | 33800 | 1200 | 325 | 160 | 38x10 | 188 | 370 | 180 |

| MG1100 | 78400 | 350 | — | 185 | 45x14 | 260 | 470 | 250 |

| MG1200 | 95100 | 300 | — | 200 | 45x14 | 260 | 500 | 250 |

| MG1300 | 176400 | 250 | — | 250 | 56x17.5 | 280 | 600 | 260 |

| Model | D | E | F | S | H-M cavity | Lubricant plug | Oil(cc) | Weight (kg) |

| MG300 | 66 | 10.4 | 28.5 | 13 | 4xM6xP1.0 | M6xP1.0 | 25 | 1.8 |

| MG400 | 73 | 10.7 | 31.7 | 16 | 4xM8xP1.25 | M6xP1.0 | 30 | 2.7 |

| MG500 | 92 | 12.3 | 44.4 | 16 | 4xM8xP1.25 | M6xP1.0 | 50 | 5 |

| MG600 | 120 | 12.8 | 69.8 | 16 | 6xM8xP1.25 | M6xP1.0 | 80 | 8.6 |

| MG700 | 160 | 19.8 | 101.5 | 20 | 6xM10xP1.5 | M6xP1.0 | 135 | 19.5 |

| MG750 | 175 | 75 | 110 | 25 | 8xM14xP2.0 | M8xP1.25 | 400 | 37 |

| MG800 | 220 | 77.5 | 140 | 25 | 8xM16xP2.0 | M8xP1.25 | 500 | 46.5 |

| MG900 | 265 | 80 | 170 | 32 | 10xM16xP2.0 | M8xP1.25 | 620 | 70.5 |

| MG1000 | 325 | 90 | 200 | 32 | 12xM16xP2.0 | M8xP1.25 | 850 | 108.5 |

| MG1100 | 415 | 125 | 260 | 40 | 12xM20xP2.5 | M12xP1.75 | 2900 | 250 |

| MG1200 | 440 | 125 | 280 | 45 | 12xM24xP3.0 | M12xP1.75 | 3000 | 280 |

| MG1300 | 530 | 130 | 340 | 50 | 12xM30xP3.5 | M12xP1.75 | 3800 | 410 |

Installation and use

The MG series cam clutch is used for low-speed overtaking in the inner ring

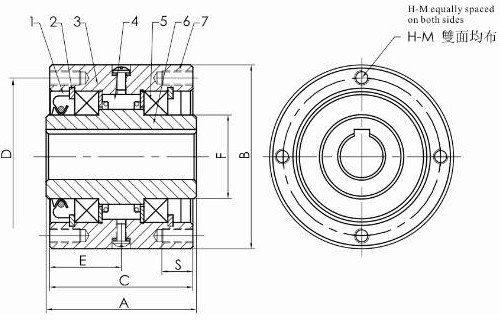

When attaching pulleys, gears, or sprockets to the clutch, insert the clutch into the hub of the side device and screw high tensile strength bolts into the threaded holes on the clutch end face. The inner hole of the wheel hub should comply with the H6 or H7 tolerance level of JIS standards (as shown in the diagram).

The recommended shaft tolerances are shown in the following table:

| Model | Public errand |

| MG300,MG400 | 0,-0.021 |

| MG500,MG600 | 0,-0.025 |

| MG700 | 0,-0.030 |

| MG750,MG800 | 0,-0.035 |

| MG900,MG1000 | 0,-0.040 |

| MG1100,MG1200,MG1300 | 0,-0.046 |

The key should comply with JIS standard B1301-1959, but for models MG750 and above, it is an additional key.

Please only use flat keys to secure the clutch to the shaft, do not use tapered keys.

It is best to use hardened keys and shafts when the clutch operates under impact loads or is solely used for anti reverse purposes.

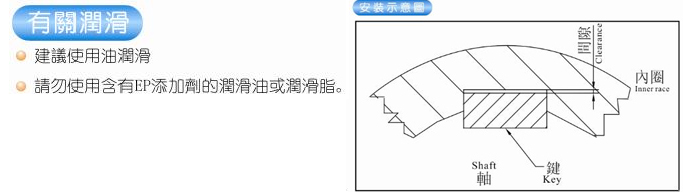

In the MG series clutch, a gap needs to be left between the top of the clutch keyway and the top of the key for pressure ventilation. And a pressure ventilation hole is provided on the keyway of the clutch inner ring.

When installing the clutch onto the shaft, apply pressure to the inner ring instead of the outer ring.

Other devices should be used instead of cam clutches to absorb thrust loads.

When applying the MG series cam clutch to medium and high-speed situations, please pay attention to overheating. When the outer ring temperature exceeds 70 ℃, the lifespan of the cam clutch will be shortened. At this point, other types of clutches should be used or oil baths or forced lubrication should be provided.

This type of clutch is not sealed with lubricating oil before shipment. Please add an appropriate amount of lubricating oil before use.

When ordering clutches of MG750 and above models in the MG series cam clutch, please inform Stdier of the overtaking speed to be achieved.