B200 SERIES CAM CLUTCHES

B200(B203-B214) SERIES CAM CLUTCHES

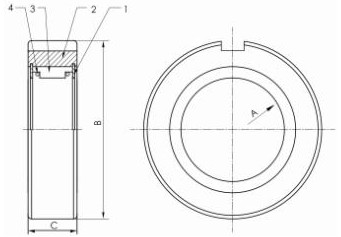

1. Baffle 2. Outer ring 2. Cam 3. Baffle 4. Spring

Other introductions:

Size and performance

| Model | Torque Capacity | Max.Overrunning | Bore Size A | Outer diameter of outer ring B | Length C | Keyway | Weight | |

| Shaft | Outer Race | |||||||

| N.m | r/min | r/min | H7(mm) | H7(mm) | (mm) | (mm) | kg | |

| B203 | 39.2 | 2400 | 500 | 16.51 | 40 -0.014 -0.039 | 25 | 4x2.5 | 0.23 |

| B204 | 58.8 | 2400 | 500 | 18.796 | 47 -0.014 -0.039 | 25 | 5x3 | 0.34 |

| B205 | 98 | 1800 | 400 | 23.622 | 52 -0.017 -0.042 | 25 | 5x3 | 0.45 |

| B206 | 235 | 1800 | 350 | 32.766 | 62 -0.017 -0.042 | 28 | 7x4 | 0.68 |

| B207 | 372 | 1800 | 300 | 42.088 | 72 -0.017 -0.042 | 28 | 7x4 | 0.8 |

| B208 | 549 | 1800 | 200 | 46.761 | 80 -0.017 -0.042 | 32 | 10x4.5 | 0.91 |

| B209 | 549 | 1800 | 200 | 46.761 | 85 -0.020 -0.045 | 32 | 10x4.5 | 0.95 |

| B210 | 784 | 1200 | 200 | 56.109 | 90 -0.020 -0.045 | 32 | 10x4.5 | 1 |

| B211 | 784 | 1200 | 200 | 56.109 | 100 -0.020 -0.050 | 32 | 10x4.5 | 1.4 |

| B212 | 1230 | 1200 | 180 | 70.029 | 110 -0.020 -0.050 | 42 | 10x4.5 | 1.8 |

| B213 | 1230 | 1200 | 180 | 70.029 | 120 -0.020 -0.050 | 42 | 10x4.5 | 2.3 |

| B214 | 1390 | 1000 | 180 | 79.356 | 125 -0.024 -0.060 | 42 | 12x4.5 | 2.4 |

Installation and use

The 200 series cam clutch is a fixed shaft type, so the hardness of the shaft connected to the clutch must be greater than HRC56-60, and the hardness after grinding should be greater than 1.2mm, with a grinding accuracy of 1.5 levels. The taper of every 50mm long shaft should not exceed 0.01mm.

During installation, avoid using a hammer to directly strike the cam clutch. The cam clutch must be installed on the shaft according to the direction of rotation indicated by the arrow. When installing the cam clutch, the two ends of the clutch should be fixed with shafts to ensure the coaxiality between the shaft and the outer ring of the cam clutch, in order to absorb the load that may be applied radially to the outer ring. The concentricity between the bracket hole and the shaft should be within 0.05mm. The shape of the key should comply with the requirements of JIS B1301-1959.

The hole tolerance on one side of the bracket assembled with the cam clutch meets the following range:

B203 B204-0 to 0.03

B205 B206 B207 B208 B209--0 to 0.025

B210 B211 B212 B213--0 to 0.035 B214-0 to 0.040