AS SERIES CAM CLUTCHES

AS(AS8-AS60) SERIES CAM CLUTCHES

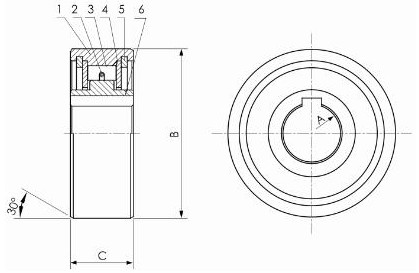

1. Outer ring 2. Spring 3. Cam 4. Baffle 5. Collar 6. Inner ring

Other introductions:

Size and performance

| Model | Torque Capacity | Max.Overrunning | Bore Size | B | Length C | Keyway | Weight | |

| Shaft | Outer Race | |||||||

| N.m | r/min | r/min | H7(mm) | H7(mm) | (mm) | (mm) | g | |

| AS8 | 6.7 | 6000 | 3000 | 8 | 24 | 8 | 1x1.0 | 14 |

| AS10 | 12 | 4500 | 2300 | 10 | 30 | 9 | 3x1.4 | 27 |

| AS12 | 17 | 4000 | 2000 | 12 | 32 | 10 | 4x1.8 | 31 |

| AS15 | 22 | 3500 | 1800 | 15 | 35 | 11 | 5x1.2 | 39 |

| AS20 | 41 | 2600 | 1300 | 20 | 47 | 14 | 6x1.6 | 115 |

| AS25 | 56 | 2200 | 1100 | 25 | 52 | 15 | 8x2.0 | 140 |

| AS30 | 105 | 1800 | 900 | 30 | 62 | 16 | 8x2.0 | 215 |

| AS35 | 136 | 1600 | 800 | 35 | 72 | 17 | 10x2.4 | 300 |

| AS40 | 296 | 1400 | 700 | 40 | 80 | 18 | 12x2.2 | 425 |

| AS45 | 347 | 1300 | 650 | 45 | 85 | 19 | 14x2.1 | 495 |

| AS50 | 403 | 1200 | 600 | 50 | 90 | 20 | 14x2.1 | 545 |

| AS60 | 649 | 910 | 460 | 60 | 110 | 22 | 18x2.3 | 950 |

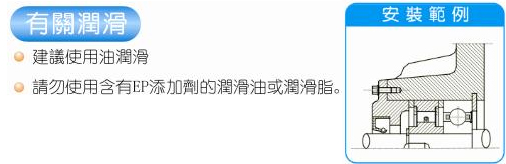

Installation and use

The outer ring and bracket of the AS series cam clutch are designed in a press fit manner. The accuracy of surface dimensions must be ensured. To achieve the best usage effect.

The inner diameter of the bracket should adopt H7 level tolerance, and during installation, the following fourth instruction should be followed. Please ensure that the bracket has sufficient strength to withstand the pressure required for installing the cam clutch.

When installing a cam clutch, a 62 type bearing should be used to withstand radial force, as this type of clutch does not have bearings installed inside. Please confirm if the rotation direction is correct before installation.

Please select the appropriate key shear force according to your design standards.

The recommended tolerance for the shaft is grade H7, while the external dimensions of the key should follow the following standards: AS15~AS60--DIN6885.1

AS15~AS60--DIN6885.3